Microfiber is an innovation in synthetic fibers developed in the early 21st century. Since its creation, it has been used successfully in the application of cleaning products. With its high absorbency, proven decontamination effectiveness, resistance to mildew and odors, greater efficacy and superior performance properties compared to traditional cotton fibers, microfiber products have replaced traditional cotton products in many homes and businesses. As microfiber is still a relatively new development, new product applications are frequently being invented and brought to market.

In 2001, when microfiber was still in its conceptual phase, it was being analyzed, studied, and tested in China by a team of young professionals. The goal was to maximize the performance of microfiber and develop highly effective and efficient product applications.

In early 2002, the founder of Eurow O’Reilly Corp. Mr. Ray O'Reilly, took a small sample of microfiber cloth to China. After receiving the sample, the team spent the duration of the year conducting raw material analysis, sample selections and dyeing process tests in an effort to produce a high quality microfiber towel. At the end of 2002,the new Microfiber Terry Cleaning Towel was realized. Mr. Ray O'Reilly immediately marketed the finished product to Costco Wholesale Corp. (Costco) and it was immediately recognized by them as a product that consumers and businesses would want and need.

Since 2003, the product at Costco has evolved from its original 12 pack to a 24 pack to its current Kirkland Signature 36 pack. The famous yellow microfiber towel can be seen and purchased in countries all over the world, such as the United States, Canada, Britain, France, Mexico, Japan, Australia and fourteen additional countries and regions. No matter where Costco has chosen to expand, the 36 pack continues to sell with tremendous success. With significant double-digit sales percentage growth year-over-year, it's one of Costco's best selling products.

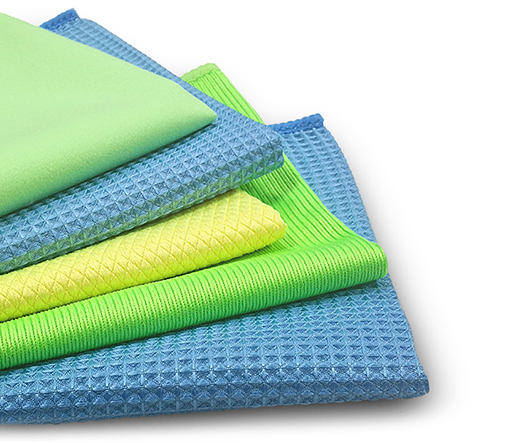

Since 2003, Hainuo has heavily invested time, finances and other resources to develop the highest quality, most effective, and best value microfiber products. Examples include: cleaning towels, kitchen towels, glass towels, cleaning mitts, cleaning sponges, cleaning pads, cleaning mops, cleaning mats and bath towels. Offering hundreds of variations in microfiber cleaning towels for household, automotive, office, and commercial applications.

In 2005, we developed and produced the Microfiber Waffle Weave Kitchen Towel for Costco and began producing products sold in AutoZone starting with eight products and tripling to twenty-five.

In 2006, we produced a total of forty-eight products sold in Pep Boys.

In 2007, we began to produce products for Sam's Club.

In 2008, our products could be purchased at Walgreens, Napa Auto Parts and Birgma in northern Europe.

Continuous product innovation, offering the best prices, producing the highest quality, and providing the fastest service are the tenets of Hainuo. Our goal of developing twenty to thirty new products each year, keeps Hainuo at the forefront of the microfiber product marketplace and benefits our clients with new sales opportunities and growth year-over-year.

Hainuo offers high production capacity with a full range of production processes, from spinning, weaving, dyeing, cutting, sewing and packing. Each process is executed utilizing the most advanced techniques available to increase efficiencies, reduce waste and ultimately mitigate and control manufacturing costs. In addition, through economic and market analytics and forecasting, we can purchase raw materials at the lowest costs possible at optimum quantities to ensure a stable price advantage for our customers.

Hainuo has an experienced and proven lean team with robust and positive energy and vibrant personalities that provide a professional and personable experience for our clients. From the development of new products to the production of an order, whether it’s a one-time 10 million piece order or small custom order of hundreds of pieces, Hainuo can do it on time and on budget. Regardless of the product specifications or complexity of the design, Hainuo’s cut and sew operations can consistently and accurately deliver quality finished goods at the desired quantities by the requested fulfillment date.

Hainuo has grown into one of the world’s largest and most successful suppliers in microfiber products and our customers have directly benefitted and have realized their own tremendous success stories. Through strategic planning, investments, win-win partnerships, a commitment to quality control, process improvement, innovation, and new product development, Hainuo has become a leader in the microfiber industry and will continue to be at the forefront for years to come.

End to end process control from procurement of raw materials to quality control and precise microfiber manufacturing systems and production technologies.

Refined selection of high quality raw materials and finely subdivided polyester and polyamide compositions. The composition of microfiber yarn varies from 70/30, 75/25, 80/20, 85/15 to 90/10. We utilize our extensive knowledge and expertise to suggest the best composition and specifications for each client request to best meet our clients’ needs and budgets.

Advanced dyeing craftsmanship and engineering. The major technological challenge with microfiber lies within the dyeing process. Regardless of the quality and composition of the materials used, if the dyeing process does not achieve the optimal opening or splitting of the fibers, the performance of the microfiber will be significantly compromised. The degree to which the fibers are split, time of process, control of temperature, and dye solution will determine the final quality of the microfiber. Because this process is of utmost importance, Hainuo has invested considerable resources to implement the best practices that can ensure an absolute and desired outcome.

Proven production process. Hainuo utilizes detailed production processes and organized process management for each order to avoid haphazard and costly mistakes. After each order is completed, the responsible team will always summarize, analyze, and discuss the project to continuously improve processes, systems, services and product quality.

Proactive planning and management. Every important task undertaken at Hainuo requires a well thought out plan of execution creating a stable and systematic work environment that can be measured and managed effectively. Each step from pre-production preparation, actual production of the order, post-production analysis to follow-up and feedback from the customer, are completed to the customer’s complete satisfaction.

Customer-centric and focused business culture. Every single order receives the highest quality and service to meet and exceed our customers’ expectations. We work in partnership with our customers and carefully create the best solution and anticipate any potential problems to ensure the best outcome for all. Regardless of preparation, problems can occur. Our focus is solving the problem quickly and completely to ensure production goals are still met and to find the root cause of the issue so that it can be addressed and prevented in the future. Since the inception of our company, we have relied on a rigorous work ethic and determination to overcome all obstacles and challenges, both big and small. We have learned and improved tremendously and are better prepared and capable to provide our customers the best services and products. We truly strive for 100% customer satisfaction and developing lifelong partnerships that benefit all.

Core product innovations to lead the microfiber industry. Every year, since Hainuo began, has equated to a year of research and new product development. From the initial launch of eight to ten products each year to the current twenty to thirty a year, our sole purpose in product innovation is to create new sales opportunities and increased market share for our customers and to share in their successes as they become leaders in their respective enterprises all over the world. Developing new products, new materials, new functions, new applications, and new packaging is the life force of Hainuo. As we have proven historically, we will continue to focus and heavily invest in new product developments and innovations for the future.